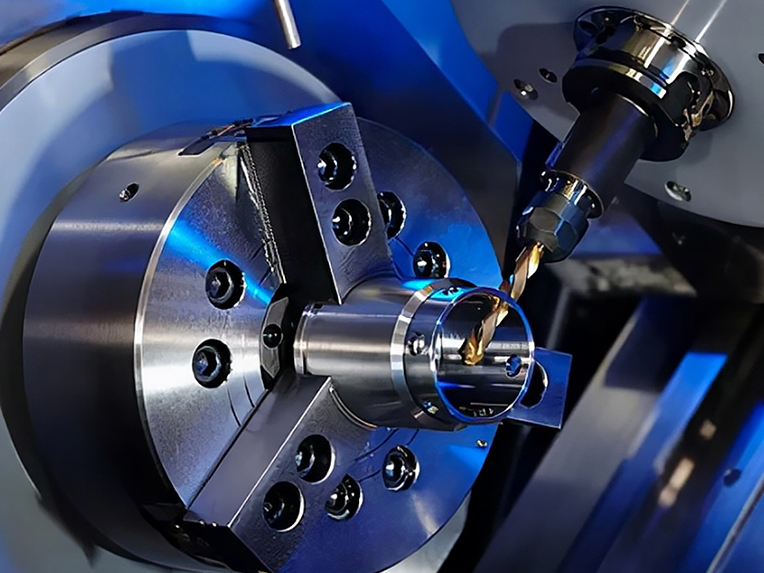

3/4/5 Axis CNC Machining

Big Brand Machines

Quality guaranteed with FANUC, HAAS, BROTHER, and more

High Quality Guarantee

TESA/Zeiss CMM devices ensure precision; 99.8% ultra-high quality rate

Welcome Small Orders

Low prices, fast delivery, even for 1 piece

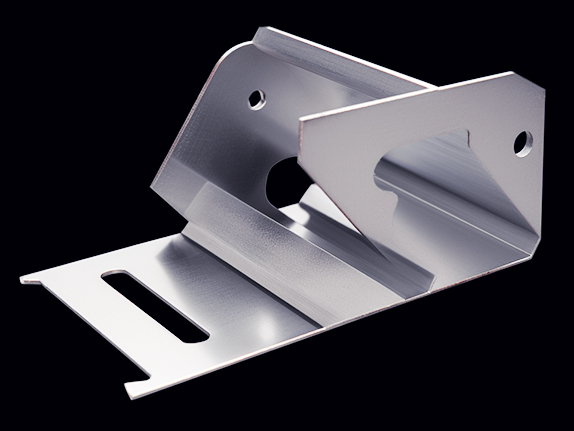

Materials that are ChooseZ machined

Typical materials that are precision CNC machined include:

PART STUDY

How to assure the precise dimensions of big-sized parts?

Raw Material

Surface Treatment

Challenge

Size is very big, 338mm(L) x167m(W) x 146mm(H), High precision requirements, multiple size requirements are ±0.01-0.012mm. Before cooperating with ChooseZ, we had 3 suppliers who produced this part, but all of them failed; ChooseZ treated the workpiece as seriously as an exquisite artwork, they focused whole on it and not afraid of difficulties, and finally succeeded after 45 days and nights. We really admire their craftsman spirit!

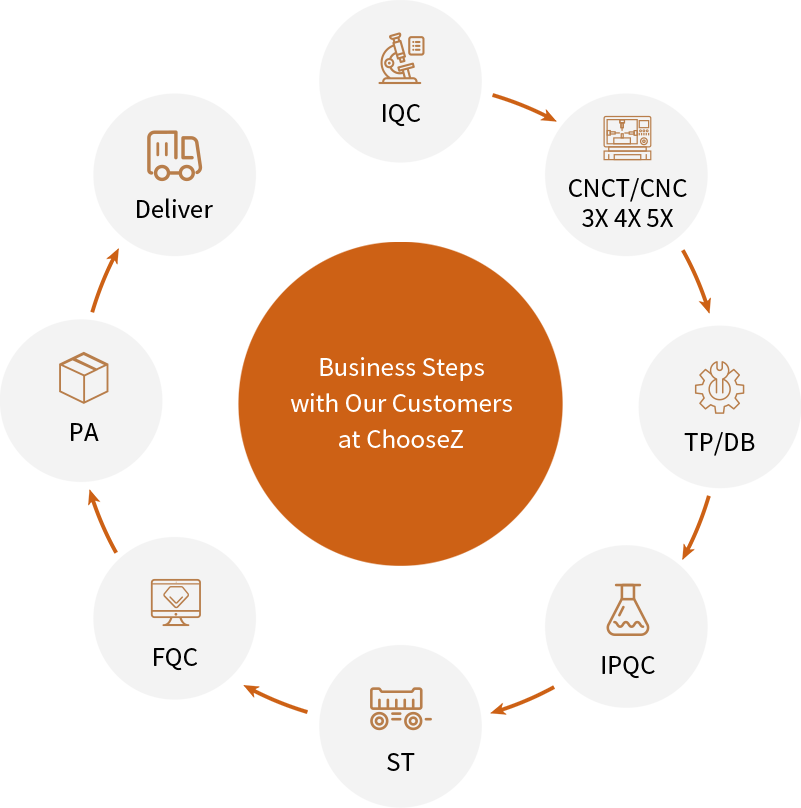

How your order will go at ChooseZ?

Basic knowledge About CNC Machining:

Understanding CNC Machining: A Comprehensive Overview

CNC machining, or Computer Numerical Control machining, is a manufacturing process that utilizes computerized systems to control machine tools. It involves the precise removal of material from a workpiece to create intricate designs and prototypes. CNC machines are programmed using specialized software, allowing for high precision and repeatability in the production of components for various industries.

Navigating CNC Dimensions: 3, 4, and 5-Axis Machining

CNC machining evolves through three dimensions, each unlocking new possibilities. In 3-axis CNC machining, the tool maneuvers along X, Y, and Z axes, suitable for simpler designs but requiring repositioning. Introducing a fourth axis enables rotational movement, reducing the need for repositioning in 4-axis CNC machining. The pinnacle is reached with 5-axis CNC machining, where the tool not only moves in all three axes but also tilts and rotates. This dynamic capability allows intricate designs without repositioning, ideal for industries demanding unparalleled precision, like aerospace and medical. The progression from 3 to 5 axes brings efficiency, complexity, and precision to the forefront of CNC machining.

Key Components of CNC Machining Systems

CNC machining systems consist of crucial components, including the machine tool (such as mills, lathes, or routers), the CNC controller, and the cutting tools. The machine tool executes the physical tasks, the CNC controller interprets the programmed instructions, and cutting tools perform material removal. Understanding the synergy between these components is fundamental for efficient CNC operations.

Programming CNC Machines: The Heart of Precision

CNC machining relies heavily on accurate programming. This involves creating a set of instructions that guide the machine tool through precise movements and cuts. Proficiency in programming languages like G-code is essential. A solid grasp of these programming principles enables machinists to translate design specifications into tangible, high-quality machined parts.

Tooling in CNC Machining: Maximizing Efficiency and Precision

Tool selection and management are critical aspects of CNC machining. Machinists must choose the right cutting tools based on factors like material type, hardness, and desired finish. Proper tool maintenance and monitoring ensure consistent quality, efficiency, and longevity in the machining process.

Quality Control and Inspection in CNC Machining

Maintaining high-quality standards is paramount in CNC machining. Machined parts undergo rigorous inspection using tools like Coordinate Measuring Machines (CMM) to verify dimensions and tolerances. Machinists must possess a keen eye for detail, understanding how to interpret inspection data and make adjustments to ensure the final product meets specifications.

FAQs

Do you only do machining or does it extend to surface treatment, assembly and other work?

We handle complete projects aligned with your drawings, covering machining, surface treatment, assembly, and more. To ensure accuracy, your drawings should specify surface treatment needs and standard parts models for assembly.

What drawing formats you can accept?

We accept various drawing formats, including DWG, DXF, STEP, IGES, and PDF, among others. If you have specific format requirements, please let us know, and we'll do our best to accommodate them.

How long does it take for you to provide a quote after I submitted the drawings?

First, we will comprehensively review the drawings to see if they are complete. After confirming that they are OK, the quotation will be provided within 24 working hours.

How do you guarantee product quality?

All products are accompanied by detailed reports before shipment. These include raw material certificate, heat treatment report (if required), surface treatment report (if required), QC report.

What thread specification can you work with?

We can work with various thread specifications, including metric, unified, and custom threads, depending on your project requirements.