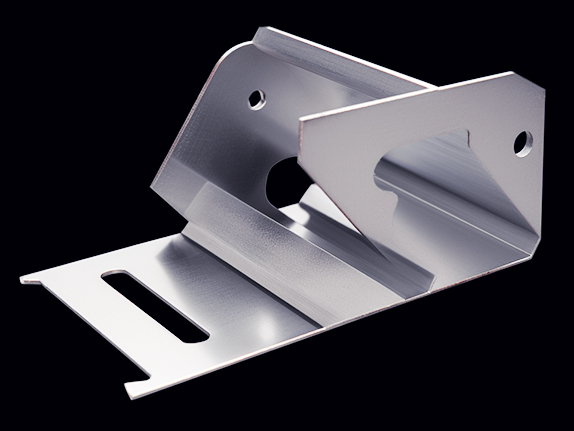

CNC Milling Service

98.5% OTD

3-day lead time, 98.5% On-Time Delivery.

100% Customer Satisfaction

100% satisfaction from 30 customers last year.

1PCS MOQ

Expertise in high-mix, low-volume production even 1PCS order

Materials that are ChooseZ machined

Typical materials that are precision CNC machined include:

PART STUDY

How to assure the precise dimensions of big-sized parts?

Raw Material

Surface Treatment

Challenge

Size is very big, 338mm(L) x167m(W) x 146mm(H), High precision requirements, multiple size requirements are ±0.01-0.012mm. Before cooperating with ChooseZ, we had 3 suppliers who produced this part, but all of them failed; ChooseZ treated the workpiece as seriously as an exquisite artwork, they focused whole on it and not afraid of difficulties, and finally succeeded after 45 days and nights. We really admire their craftsman spirit!

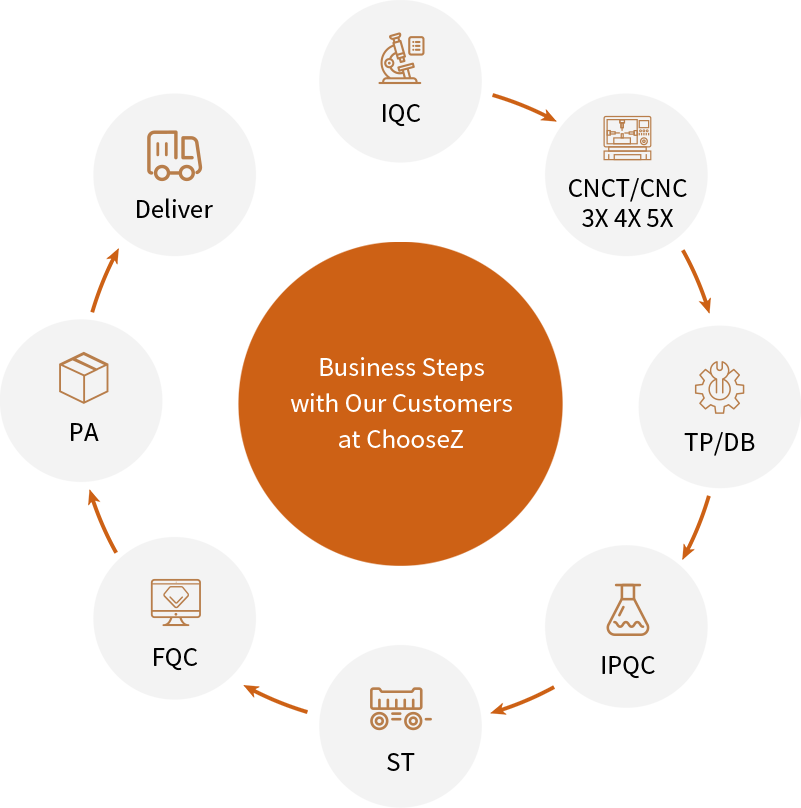

How your order will go at ChooseZ?

Basic knowledge About CNC Machining:

Understanding CNC Milling: An Overview

CNC milling is a subtractive manufacturing process that utilizes computerized controls to remove material from a workpiece. The milling machine, guided by a computer program, precisely cuts and shapes the material to achieve the desired design. This versatile process is widely used for producing components with intricate geometries, making it a cornerstone in various industries.

Tooling and Cutters in CNC Milling

Tooling is a critical aspect of CNC milling, with various cutters designed for specific tasks. End mills, ball mills, and face mills are common types, each tailored for particular cutting needs. Proper selection and maintenance of tools are crucial for achieving accurate and efficient milling results.

Workholding Techniques in CNC Milling

Securing the workpiece during milling is vital for precision. Workholding techniques include clamping, vises, and fixtures. Proper workholding ensures stability, reducing the risk of inaccuracies and improving the overall milling process.

Understanding CNC Milling Feeds and Speeds

Feeds and speeds are fundamental parameters in CNC milling that influence the cutting process. "Feed" refers to the tool's movement relative to the workpiece, while "speed" denotes the spindle's rotation. Optimizing these factors is essential for achieving efficient material removal without compromising precision.

CNC Milling Programming Basics

CNC milling programming involves creating a set of instructions for the milling machine to follow. G-code, a language understood by CNC machines, is commonly used for programming. Machinists must have a solid understanding of programming basics to generate accurate toolpaths and produce the intended designs.

Quality Control and Inspection in CNC Milling

Quality control is integral in CNC milling to ensure the final product meets design specifications. Inspection techniques, including the use of coordinate measuring machines (CMM), help verify dimensional accuracy and adherence to tolerances. Rigorous quality control processes contribute to the overall reliability of CNC-milled components.

FAQs

How do you guarantee product quality?

All products are accompanied by detailed reports before shipment. These include raw material certificate, heat treatment report (if required), surface treatment report (if required), QC report.

What is your average production lead time?

The lead time varies based on product complexity and our machine capacity. Typically, simple lathe parts take 3 days (fastest) or 5 to 7 days, while milling parts can range from 7 to 14 days. More complex projects might extend to around 42 days.

What thread specification can you work with?

We can work with various thread specifications, including metric, unified, and custom threads, depending on your project requirements.

Do you only do machining or does it extend to surface treatment, assembly and other work?

We handle complete projects aligned with your drawings, covering machining, surface treatment, assembly, and more. To ensure accuracy, your drawings should specify surface treatment needs and standard parts models for assembly.

How long does it take for you to provide a quote after I submitted the drawings?

First, we will comprehensively review the drawings to see if they are complete. After confirming that they are OK, the quotation will be provided within 24 working hours.