CNC Turning Service

Industry Leading Machinery

Quality Assurance from FANUC, HAAS, BROTHER, and others

Exceptional Quality Assurance

TESA/Zeiss CMM precision; 99.8% ultra-high quality rate

Small Orders Welcome

Low prices and swift delivery, even for 1PCS orders

Materials that are ChooseZ machined

Typical materials that are precision CNC machined include:

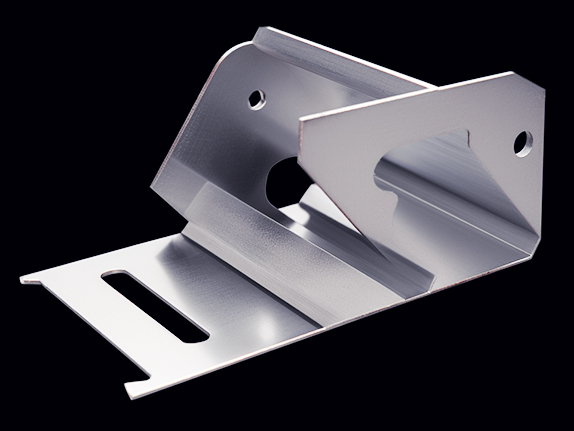

PART STUDY

How to assure the precise dimensions of big-sized parts?

Raw Material

Surface Treatment

Challenge

Size is very big, 338mm(L) x167m(W) x 146mm(H), High precision requirements, multiple size requirements are ±0.01-0.012mm. Before cooperating with ChooseZ, we had 3 suppliers who produced this part, but all of them failed; ChooseZ treated the workpiece as seriously as an exquisite artwork, they focused whole on it and not afraid of difficulties, and finally succeeded after 45 days and nights. We really admire their craftsman spirit!

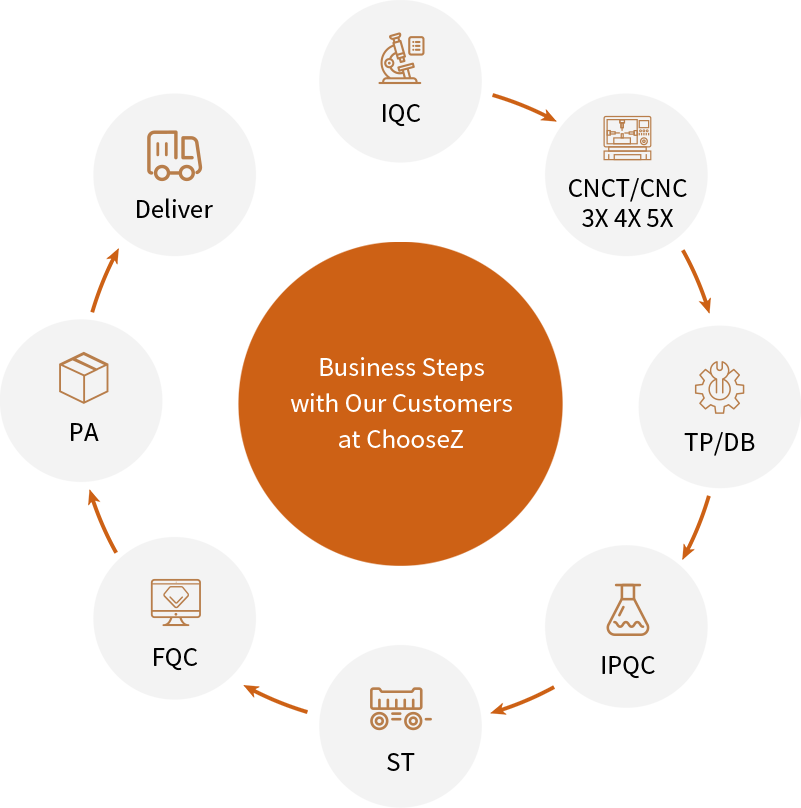

How your order will go at ChooseZ?

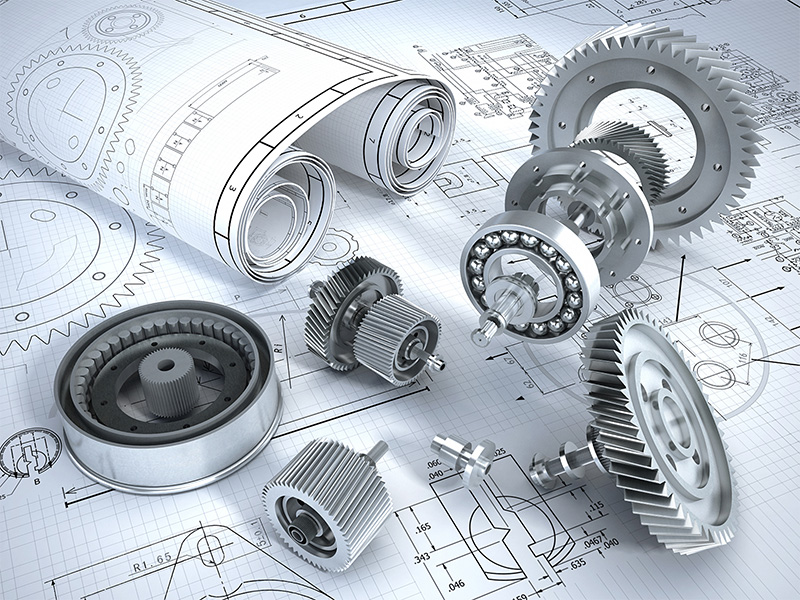

Basic knowledge About CNC Turning:

Introduction to CNC Turning: A Fundamental Overview

CNC turning is a subtractive manufacturing process that utilizes computer-controlled machines to shape cylindrical or rotational parts. During turning, a workpiece rotates while a cutting tool removes material to create the desired shape. This versatile method is widely employed for creating components like shafts, pins, and custom cylindrical parts in various industries.

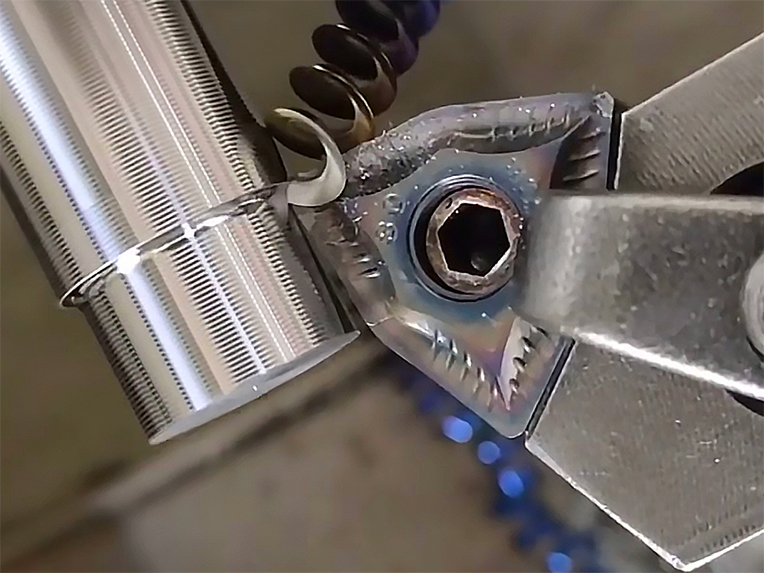

Tooling in CNC Turning: Key Components for Success

Tooling is critical in CNC turning, with tools like inserts, drills, and boring bars playing essential roles. The proper selection and maintenance of these tools are crucial for achieving accurate and efficient turning results. Understanding the various tool types and their applications is fundamental to successful CNC turning operations.

Workholding Techniques in CNC Turning

Effective workholding is paramount in CNC turning to ensure stability and precision during the machining process. Common techniques include chucks, collets, and fixtures, each serving specific purposes. Selecting the appropriate workholding method is vital to achieving the desired accuracy in turned parts.

CNC Turning Programming Basics: G-Code and Beyond

Programming is a key aspect of CNC turning, involving the creation of instructions for the machine to follow. G-code, a language understood by CNC machines, is commonly used for programming turning operations. Machinists need a solid grasp of programming basics to generate accurate toolpaths and achieve the desired turned shapes.

Understanding CNC Turning Feeds and Speeds

Feeds and speeds are crucial parameters in CNC turning, impacting the efficiency and quality of the machining process. Properly optimizing these factors is essential for achieving precise material removal without compromising the integrity of the turned components.

Distinguishing CNC Machining and Turning: Precision Insights

Precision manufacturing entails CNC machining and turning, each with unique strengths. CNC machining, a comprehensive term, involves milling, drilling, and turning. Milling crafts intricate shapes, drilling creates precise holes, and turning specializes in rotational components. In turning, the workpiece rotates as cutting tools sculpt precise cylindrical parts. CNC machining offers versatility across part geometries, while turning excels in precision for cylindrical components. The choice between these methods hinges on specific manufacturing needs, showcasing the nuanced selection in precision engineering.

FAQs

What are your inspection standards?

For FA orders, if quantity is less than 10 pieces, all quantities and sizes will be inspected. For non-FA orders, AQL standard inspection will be followed.

What drawing formats you can accept?

We accept various drawing formats, including DWG, DXF, STEP, IGES, and PDF, among others. If you have specific format requirements, please let us know, and we'll do our best to accommodate them.

What is your average production lead time?

The lead time varies based on product complexity and our machine capacity. Typically, simple lathe parts take 3 days (fastest) or 5 to 7 days, while milling parts can range from 7 to 14 days. More complex projects might extend to around 42 days.

How do you guarantee product quality?

All products are accompanied by detailed reports before shipment. These include raw material certificate, heat treatment report (if required), surface treatment report (if required), QC report.

Do you only do machining or does it extend to surface treatment, assembly and other work?

We handle complete projects aligned with your drawings, covering machining, surface treatment, assembly, and more. To ensure accuracy, your drawings should specify surface treatment needs and standard parts models for assembly.