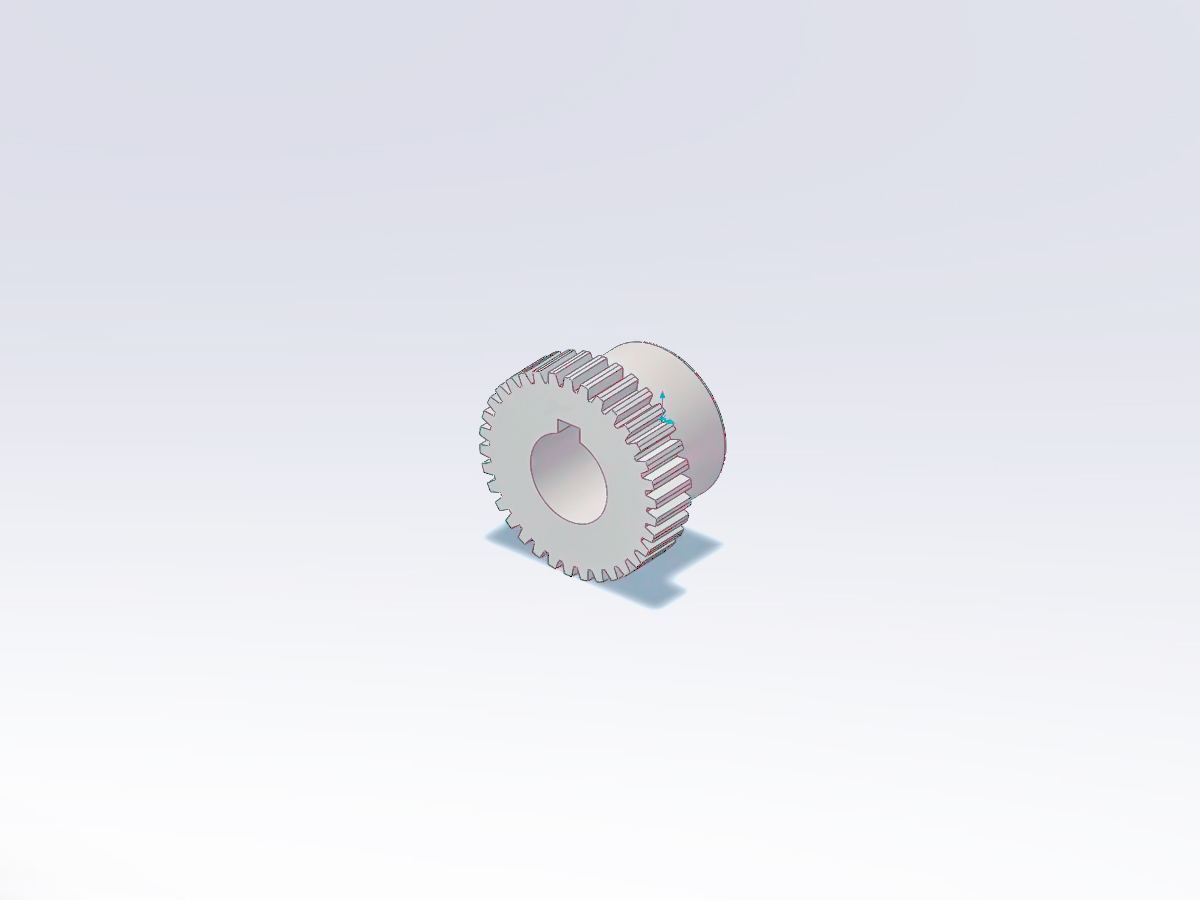

Innovating Precision in Miniature Gear Production

This case study explores the intricate process of achieving precision in miniature gear production, presenting a challenge in crafting 5mm diameter gears with tooth patterns under demanding tolerances of ±0.002mm. Leveraging advanced CNC machining, specialized alloys, and stringent quality control, ChooseZ navigated the complexities to deliver 1000 miniature gears of exceptional precision and functionality. Through innovative technology, rigorous inspection, and a commitment to detail, this case study delves into how ChooseZ surpassed the challenge, meeting the client's exacting requirements and reinforcing their dedication to precision manufacturing in miniature scales.

The Challenge

Precision Demands in Miniature Gear Manufacturing: Crafting precise miniature gears, measuring a mere 5mm in diameter, with intricate tooth patterns, demanded ultra-precise tolerances of ±0.002mm. Achieving such microscopic precision presented a significant challenge.

The Solution

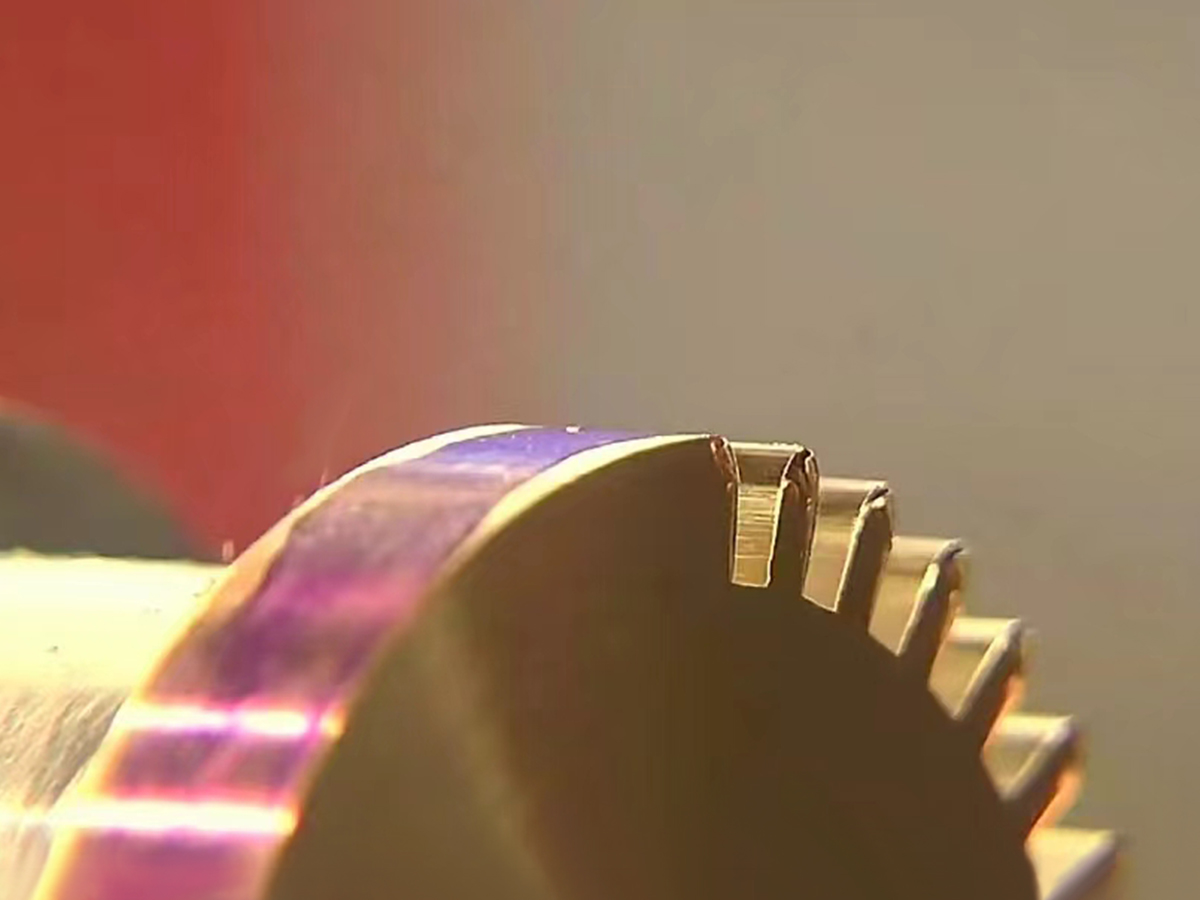

Employing high-precision CNC machining with micro-tooling and ultra-high-speed spindles, allowing intricate and accurate tooth profiling.

Utilizing specialized alloys with enhanced hardness and wear resistance to ensure gear longevity and performance. In addition, in order to minimize the impact of the material itself on the finished product, heat treatment is performed before processing.

Implementing continuous inspection cycles, including laser measurement systems and 3D scanning, to ensure each gear met the exacting tolerances.

Standardize the documentation of the process, fixtures and tools used. Before each production, the fixtures and tools must be inspected firstly. Ensure that the quality of this Gear is stable every time it is produced.

The Outcome

Customer Testimonial

"ChooseZ's expertise in crafting the microscopic gears for our precision instruments was commendable. Their attention to detail and relentless pursuit of perfection truly set them apart. The gears we received were of exceptional quality, meeting our stringent requirements for our specialized instruments. ChooseZ's commitment to precision is remarkable."

ChooseZ Comment

"Producing precision gears at such miniature scales demanded a blend of cutting-edge technology, meticulous craftsmanship, and rigorous quality control. There are many uncertain factors in this process, which need to be constantly discovered and corrected.It's a testament to our team's expertise and dedication to delivering precision in every aspect of our manufacturing process."