How Can We Ensure Precision in Large-Sized Parts Production?

The Challenge:

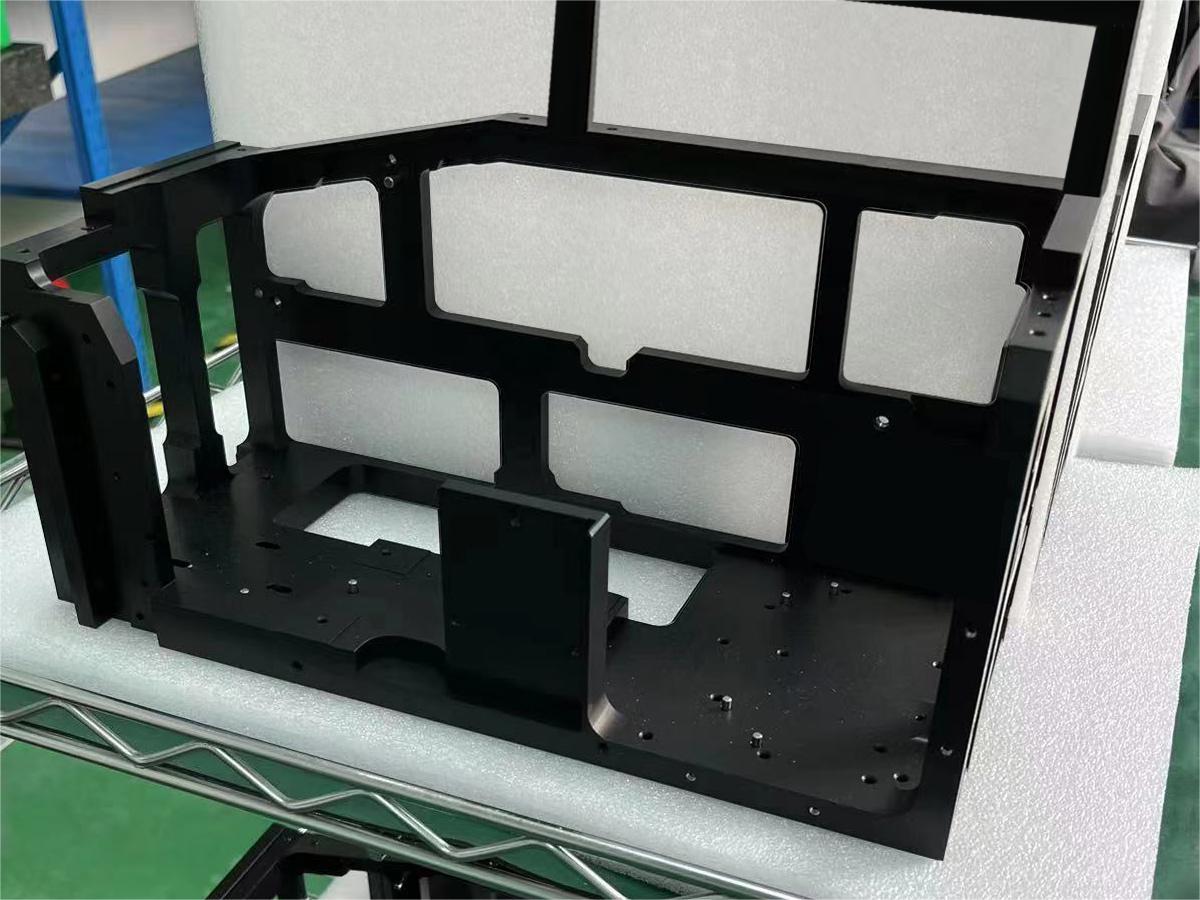

Confronted with the manufacturing of a sizeable AL 6061-T6511 component, measuring a substantial 338mm (L) x 167mm (W) x 146mm (H), the demand for precision within tolerances of ±0.01-0.012mm posed a significant challenge.

Despite meticulous attention to detail in processes, tools, and programming, we faced a perplexing problem: inconsistent inspection results from multiple stakeholders led to a discouragingly high rejection rate of parts.

The Solution:

To counteract potential material deformation, we introduced a critical phase in our manufacturing process. Heat treatment was administered after rough machining and before fine machining, ensuring that the material maintained its structural integrity.

Recognizing the pivotal role of temperature in achieving precision, we instituted a meticulously controlled environment. Parts were conditioned at normal room temperature for a duration of 2 hours prior to inspection. Subsequently, they were transferred to a specialized inspection room, equipped with air-conditioning set to a precise 20°C ± 0.2°C. The parts were allowed to reach thermal equilibrium for another 2 hours before undergoing inspection.

We also standardized our inspection process to ensure uniform reference planes, a critical aspect of precision. Our commitment to accuracy was further underscored through the implementation of CMM (Coordinate Measuring Machine) technology.

The Outcome: Exceptional Quality Control and Client Success

Customer Testimonial:

"Other suppliers failed, but ChooseZ's dedication and precision in 45 days impressed us."

"Before our collaboration with ChooseZ, we had engaged with three previous suppliers, each of whom struggled to meet the rigorous precision requirements for this component. ChooseZ treated the project with an unwavering dedication akin to an artisan crafting a masterpiece, demonstrating a remarkable spirit of craftsmanship. After 45 days and nights of tireless effort, they achieved the remarkable. We hold deep admiration for their unwavering commitment and precision."

ChooseZ Comment:

"When dealing with CNC machining for parts with exacting dimensional precision, one must consider a multitude of factors. These include environmental temperature, the methodology employed for inspection, and the choice of inspection tools. Successful outcomes can only be achieved when all these elements are meticulously aligned to complement one another."