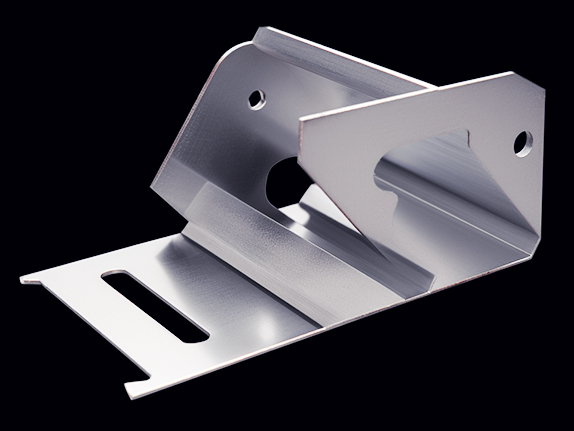

Sheet Metal Fabrication Service

No Waiting Costs

Responses within 4 hours;Orders ship out in just 3 days.

Free Personal Consultant

We don't design, but offer free advice on design for manufacturability (DFM).

Price match guarrantee

Considering delivery and cost, we can quote competitively, even for 1 piece.

Available Materials for Sheet Metal

Aluminum | Stainless steel | Mild steel | Copper |

5052 | 304 | 1018 | C110 |

5754 | 316L |

|

Available Sheet Metal Fabrication Processes

Aluminum | Stainless steel | Allowable sheet thickness |

Laser cutting | This process involves using a high-powered laser beam to cut through a sheet of material. | 1-6mm (depending on material) |

Bending | This process utilizes dies to shape ductile materials along a straight axis, forming U-shapes, V-shapes, or channel shapes. | 1-6mm (depending on material) |

Tolerances for Sheet Metal Fabrication

Feature | Tolerance |

Cutting feature | ± .00787’’ (0.2 mm) |

Bend angle | ± 1.0° |

Bend to edge | +/- 0.010” (0.254mm) |

Basic knowledge About Sheet Metal Fabrication:

Material Mastery:

Sheet metal fabrication involves transforming flat sheets into functional components. Materials like steel, aluminum, and copper are commonly used, with each offering distinct properties for varied applications.

Design Flexibility:

Sheet metal fabrication provides design flexibility, allowing for intricate and customized shapes. This adaptability caters to diverse industry needs and ensures creative freedom in product development.

Precision in Every Detail:

With a commitment to quality, sheet metal fabrication achieves precision with tight tolerances. Advanced tools and techniques ensure that each component meets specified dimensions, contributing to the overall quality of the final product.

Cutting-Edge Technology:

The process leverages cutting-edge technology, such as laser cutting and CNC punching, to achieve accurate and clean cuts. These technologies enhance efficiency, reduce waste, and contribute to cost-effective fabrication.

Welding Expertise:

Sheet metal fabrication often involves welding to assemble components. Skilled welders employ various techniques, including MIG and TIG welding, to create strong and durable joints, ensuring the structural integrity of the fabricated parts.

Rapid Turnaround:

Sheet metal fabrication offers a quick turnaround, with some projects completed in as little as a few days. This efficiency is particularly advantageous for clients with tight timelines and urgent project requirements.

FAQs

What drawing formats you can accept?

We accept various drawing formats, including DWG, DXF, STEP, IGES, and PDF, among others. If you have specific format requirements, please let us know, and we'll do our best to accommodate them.

How long does it take for you to provide a quote after I submitted the drawings?

First, we will comprehensively review the drawings to see if they are complete. After confirming that they are OK, the quotation will be provided within 24 working hours.

What are your inspection standards?

For FA orders, if quantity is less than 10 pieces, all quantities and sizes will be inspected. For non-FA orders, AQL standard inspection will be followed.

What thread specification can you work with?

We can work with various thread specifications, including metric, unified, and custom threads, depending on your project requirements.

How do you guarantee product quality?

All products are accompanied by detailed reports before shipment. These include raw material certificate, heat treatment report (if required), surface treatment report (if required), QC report.