About CNC Manufacturing- Everything

You Should Know

POSTED ON April 12

What is CNC Manufacturing?

What is CNC?

CNC stands for Computer Numerical Control. It's a technology that automates machine tools through computer commands. CNC systems interpret numerical data to control the movement of cutting tools and other machinery, enabling precise manufacturing processes.

What is CNC Manufacturing?

CNC manufacturing means the process of producing different parts and components using CNC technology. It involves cutting, shaping, and forming materials into the appropriate forms and sizes.It usually uses computer-controlled machinery, such as lathes, mills, and routers.

Which Names Sound Similar To CNC Manufacturing?

Other names for CNC manufacturing include computer-controlled machining, CNC machining, and just CNC production. These terms all describe the same process of utilizing computerized systems to automate manufacturing operations.

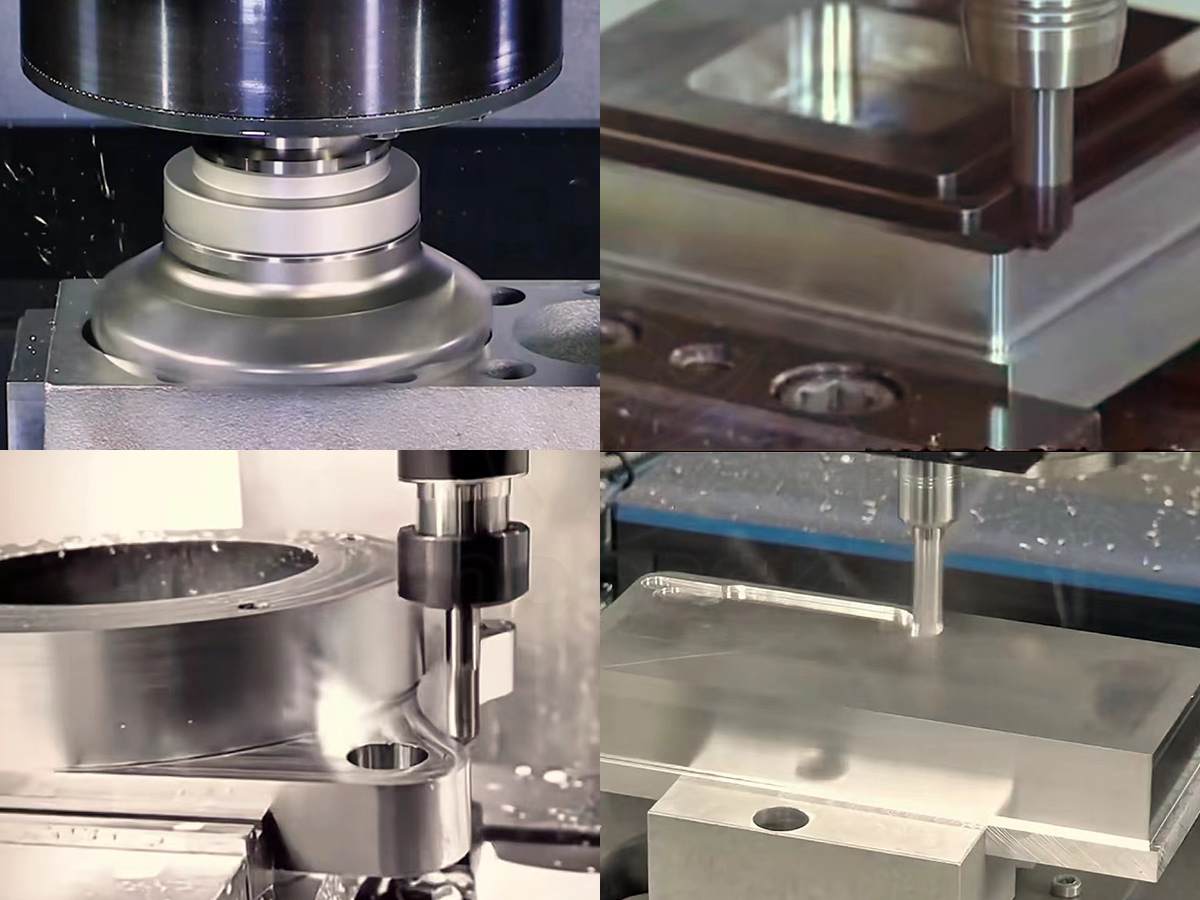

Types of CNC Manufacturing Machines and Machine Tools

A wide range of specialized tools and equipment designed to meet various manufacturing requirements are included in CNC machines. These are a few typical kinds:

CNC Milling

These devices remove material from a workpiece precisely by using rotary cutting tools to create features and shapes. They are adaptable and work well with a variety of materials, including as plastic, wood, and metal.

CNC Lathe Turning

Lathes are perfect for cylindrical pieces like shafts and rods because they rotate the workpiece while the cutting tools go along its length. They are necessary for activities such as threading, facing, and turning.

CNC Routers

Materials including wood, plastic, and composites can be carved, engraved, and cut with routers. They are widely used in woodworking, signage, and prototyping industries.

CNC Plasma Cutters

These machines use high-speed jets of ionized gas to cut conductive materials such as steel, aluminum and copper. They are commonly used in metal fabrication and industrial applications.

CNC Waterjet Cutters

Waterjet cutting machines use a high-pressure stream of water mixed with abrasive particles to cut a variety of materials, including metals, ceramics and glass. They provide precise cuts with minimal heat affected zones.

CNC Laser Cutters

Laser cutters use a focused laser beam to cut materials with high precision and speed. They are suitable for intricate designs and delicate materials such as acrylics, fabrics and thin metals.

Role of CNC Machinists

CNC machinists play a crucial role in the manufacturing process, overseeing the operation of CNC machines and ensuring the production of high-quality parts. Here are some key responsibilities and skills associated with the role:

Programming: CNC machinists are proficient in writing and editing CNC programs that dictate the movements and actions of the machine tools. They design toolpaths and maximize machining operations using CAD/CAM software.

Setup and Operation: Machinists load materials, install cutting tools, and secure workpieces on CNC machines in accordance with job specifications. They keep an eye on how the machines are operating and change them as needed to keep the quality and efficiency high.

Tooling and Tool Management: Based on the specifications of the work and the characteristics of the material, machinists choose the right cutting tools. To guarantee optimum performance and tool lifetime, they carry out tool changes, tool offsets, and tool life management.

Quality Control: To ensure that part dimensions, surface finishes, and tolerance compliance are met, machinists carry out both final quality checks and in-process inspections. To confirm part accuracy, they employ precision measurement tools like gauges, micrometers, and calipers.

Solving problems: During machining operations, machinists troubleshoot problems such tool wear, machine faults, or programming errors. To reduce downtime and scrap, they pinpoint the underlying reasons and put corrective measures in place.

Safety and Maintenance: To avoid mishaps and injuries in the workshop, machinists follow safety procedures and industry best practices. To guarantee the lifetime and dependability of the equipment, they carry out standard maintenance procedures on CNC machines, including lubrication, cleaning, and small repairs.

What Is the Process of CNC Manufacturing?

Computer Numerical Control (CNC) manufacturing converts raw materials into completed items by use of a carefully planned sequence of operations. This is a condensed explanation of the procedure:

Design and Programming: Using specialist software such as Computer-Aided Design (CAD), engineers create a digital blueprint of the intended component. Next, CNC programmers use Computer-Aided Manufacturing (CAM) software to convert this design into machine-readable instructions, or G-code.

Machine Setup: The CNC machine is ready for use by knowledgeable CNC machinists. This entails placing the necessary cutting tools on the machine bed after loading the raw material, making sure everything is firmly in position.

Command Execution: The CNC machine's computer reads the G-code, loads the instructions, and moves the cutting tools precisely along predefined pathways. In order to shape the workpiece in accordance with the design, these routes specify how material must be removed.

Material Removal: To shape the workpiece into the desired shape, the cutting tools gradually remove surplus material from the raw stock under the direction of the CNC machine's program. Until the required shape and dimensions are obtained, this process is repeated.

Real-time Monitoring: Sensors and monitoring systems monitor critical parameters including material temperature, tool engagement, and cutting speed throughout the machining process. In order to preserve accuracy and efficiency, any deviations from the specified parameters demand corrections.

Quality Assurance: As the workpiece is being machined, machinists check it on a regular basis to make sure it satisfies the necessary requirements. To maintain strict standards, this may entail dimensions checks, surface finish assessments, and other quality control procedures..

Post-Processing: To enhance the part's functioning or appearance, more finishing touches may be performed after machining is finished. This could entail steps like polishing, deburring, and providing protective coatings as necessary.

Final Inspection and Packaging: To ensure quality and accuracy, the completed parts go through a comprehensive inspection. After passing inspection, parts are wrapped with care and ready to be shipped to clients or assembled into larger products.

Applications of CNC Manufacturing

Because CNC production offers unmatched precision, efficiency, and versatility, it has transformed a number of industries. Among the important applications are:

Automobile Sector: In the automotive industry, CNC machining is widely utilized to produce engine, gearbox, brake, and complex chassis components with tight tolerances and high durability requirements.

Aerospace and Defense: CNC manufacturing is essential in the aerospace and defense industry for producing intricate parts for airplanes, missile systems, satellites, and structural elements that require exact geometries and lightweight, durable materials.

Medical Devices: To achieve exacting regulatory requirements, medical professionals rely on CNC machining to create surgical instruments, implants, prosthesis, and other equipment with extraordinary precision, biocompatibility, and sterile qualities.

Electronics: To create circuit boards, connectors, housings, and complex electronic components with exact dimensions, intricate geometries, and superb surface finishes, the electronics sector depends on CNC production.

Tool and Die Making: High reproducibility, accuracy, and efficiency in mass production are made possible by CNC machining, which is essential in the fabrication of molds, dies, jigs, and fixtures used in manufacturing processes.

Consumer Goods: CNC manufacturing caters to the production of consumer goods such as watches, jewelry, eyewear, and customized products, offering intricate designs, fine details, and high-quality finishes to meet consumer demands.

Prototyping and Rapid Manufacturing: CNC machining is widely employed in prototyping and rapid manufacturing processes to quickly produce functional prototypes, iterate designs, and accelerate product development cycles with minimal lead times.

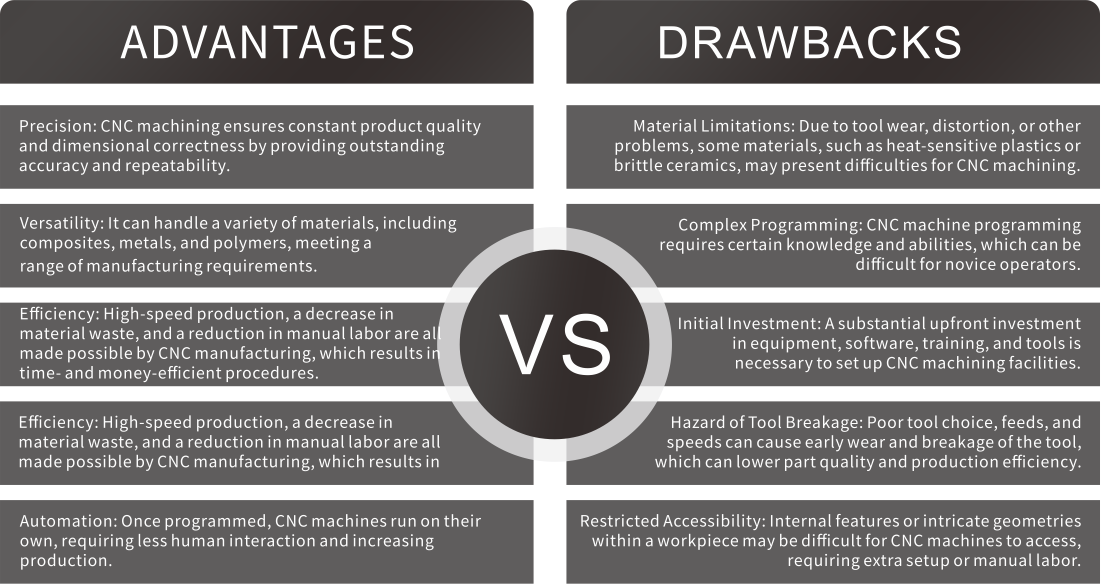

Advantages and Drawbacks of CNC Manufacturing

CNC manufacturing offers benefits and drawbacks like any other production technique:

Advantages:

Precision: CNC machining ensures constant product quality and dimensional correctness by providing outstanding accuracy and repeatability.

Versatility: It can handle a variety of materials, including composites, metals, and polymers, meeting a range of manufacturing requirements.

Efficiency: High-speed production, a decrease in material waste, and a reduction in manual labor are all made possible by CNC manufacturing, which results in time- and money-efficient procedures.

Complex Geometry: It can easily create complex and detailed geometries, enabling the creation of highly specialized and bespoke components.

Automation: Once programmed, CNC machines run on their own, requiring less human interaction and increasing production.

Drawbacks:

Initial Investment: A substantial upfront investment in equipment, software, training, and tools is necessary to set up CNC machining facilities.

Complex Programming: CNC machine programming requires certain knowledge and abilities, which can be difficult for novice operators.

Material Limitations: Due to tool wear, distortion, or other problems, some materials, such as heat-sensitive plastics or brittle ceramics, may present difficulties for CNC machining.

Hazard of Tool Breakage: Poor tool choice, feeds, and speeds can cause early wear and breakage of the tool, which can lower part quality and production efficiency.

Restricted Accessibility: Internal features or intricate geometries within a workpiece may be difficult for CNC machines to access, requiring extra setup or manual labor.

Despite these limitations, the advantages of CNC manufacturing outweigh its drawbacks, making it a preferred choice for a wide range of industries seeking precision, efficiency, and flexibility in production processes.

Difficulties And Restrictions In CNC Manufacturing

Notwithstanding its many advantages, CNC production has a number of drawbacks and difficulties.

Difficulties:

Complex Programming: CNC machine programming calls for certain knowledge and abilities, which might be difficult for operators who are not familiar with CAD/CAM software or G-code programming.

High Initial Investment: It might be difficult for small enterprises or startups to embrace CNC manufacturing due to the upfront expenses involved in buying CNC machines, tooling, software, and training.

Material Selection: Because of their hardness, abrasiveness, or thermal characteristics, some materials—such as heat-resistant alloys or unusual metals—may be difficult to machine using CNC machines, requiring the use of specialist tools and cutting techniques.

Tool Wear and Maintenance: Continuous use of cutting tools in CNC machining leads to wear and eventual tool breakage, requiring frequent tool changes, maintenance, and replacement, which can increase production costs and downtime.

Surface Finish and Quality Control: Achieving the desired surface finish and dimensional accuracy in CNC manufacturing requires careful selection of cutting parameters, toolpath strategies, and machining techniques, which may pose challenges in maintaining consistent quality across batches.

Restrictions:

Complicated Geometries: CNC machining may not be able to produce very precise details, internal features, or geometries that need for specific tools, procedures, or post-machining work.

Material Compatibility: Because of their special qualities or machining characteristics, certain materials, such ceramics, composites, or heat-sensitive polymers, may be difficult to manufacture using traditional CNC techniques.

Size and Weight Restrictions: The size, weight, and dimensions of parts that can be manufactured in a single setup are limited by the constraints of CNC machines when handling large or enormous workpieces.

Production Volume: While CNC manufacturing offers high precision and repeatability, it may not be as cost-effective for low-volume production runs due to setup time, tooling costs, and programming complexity.

Environmental Impact: CNC manufacturing generates waste materials, coolant, and emissions, posing environmental challenges related to waste disposal, energy consumption, and environmental regulations compliance.

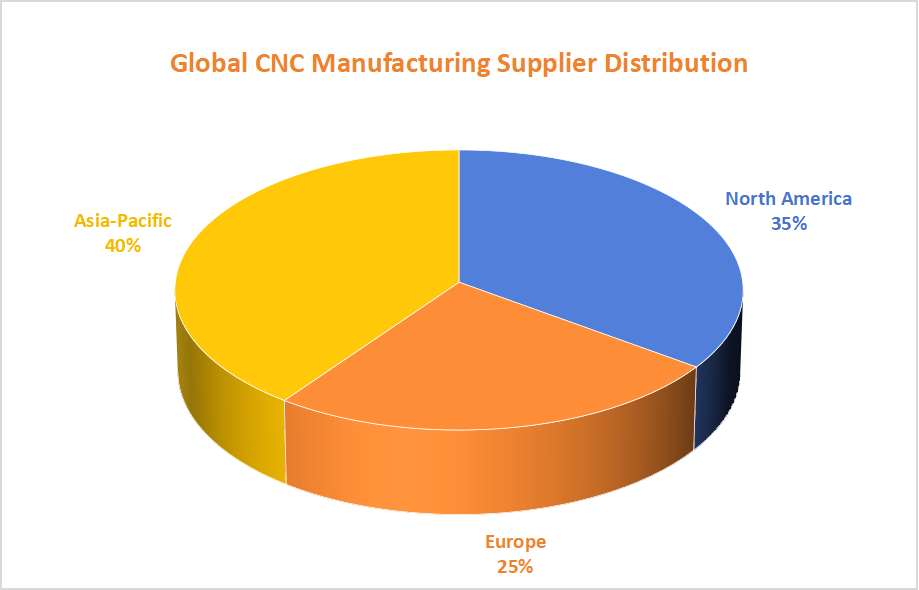

CNC Manufacturing Status Worldwide

Global CNC Manufacturing Supplier Distribution

Geographically distributed, the global CNC manufacturing sector has noticeable supplier concentrations in important production areas. According to recent data, the worldwide CNC manufacturing supply base is made up of roughly 60% of North America and Europe combined, with the other 40% being spread throughout Asia-Pacific, Latin America, and other regions.

The US leads North America in CNC production, accounting for around 35% of the distribution of suppliers worldwide. Europe is not far behind, with nations like Germany, Italy, and Switzerland making up a sizeable portion of the world's suppliers—roughly 25%—in the CNC manufacturing sector.

China is a prominent player in the Asia-Pacific region, accounting for almost 50% of the world's suppliers for CNC manufacturing. Cities like Shenzhen, Dongguan, and Shanghai host a substantial portion of these suppliers, capitalizing on China's manufacturing prowess and extensive industrial infrastructure.

CNC Manufacturing Status Worldwide

Distribution of CNC Manufacturing Suppliers in China

Region | Percentage of China's Suppliers |

Guangdong Province | 70% |

Pearl River Delta Region | 40% |

Shenzhen | 25% |

Yangtze River Delta | 15% |

Bohai Rim Region | 10% |

China's CNC manufacturing industry is highly concentrated, and Guangdong Province alone has more than 70% of the country's CNC suppliers. The Pearl River Delta region, including cities such as Shenzhen and Dongguan, accounts for nearly 40% of China's CNC manufacturing suppliers.

Furthermore, Shenzhen, known as the "Silicon Valley of Hardware," houses approximately 25% of China's CNC machining facilities. This concentration is attributed to Shenzhen's vibrant ecosystem of technology startups, electronic manufacturing companies, and access to skilled labor.

Other prominent CNC manufacturing clusters in China include the Yangtze River Delta region, centered around Shanghai, and the Bohai Rim region, encompassing cities like Beijing and Tianjin. Collectively, these regions contribute to China's status as a global leader in CNC manufacturing, with a diverse range of suppliers catering to domestic and international markets.

*The above data comes from Statista, IBISWorld, Grand View Research; government reports from organizations such as the United Nations, the World Bank and the National Bureau of Statistics of China, as well as reports from industry associations such as the China Association of Automobile Manufacturers (CAAM) and the China Machinery Industry Federation (CMIF) .

The Next Big Thing in CNC Manufacturing

Technological Evolution: Thanks to developments in automation, AI, and machine learning, CNC production is about to undergo a technological revolution.

IoT Integration: By enabling real-time monitoring and optimization, increasing productivity, and reducing downtime, the integration of IoT devices will transform CNC machines.

The rise of additive manufacturing: Similar to 3D printing, additive manufacturing will work in conjunction with CNC machining to provide new opportunities for complex item design and quick prototyping.

Demand for customisation: As industries become more reliant on customisation and agility, CNC manufacturing will see rapid advancements in response to the varied and changing demands of the industry.

Adoption of Digital Twins: Digital twin technology will revolutionize the industry by providing performance optimization, predictive maintenance, and virtual simulations of machining operations.

In essence, the future of CNC manufacturing promises to be dynamic, embracing cutting-edge technologies to enhance efficiency, flexibility, and innovation across industries.

Micheal Wu

Engineer Manager

Wu is a mechanical engineer with more than ten years of experience.His personality is not boring but very interesting. He is also very good at cooking, so he always plays the role of chef during team building.

You Might also Like

View all →

CNC Milling Machine Operation: Ready to Master the Key Skills?

Read More →

How Much Does CNC Machining Cost?

Read More →