How Much Does

CNC Machining Cost?

POSTED ON April24

Main Cost Components of CNC Machining

Raw Materials

A wide variety of raw materials, each with a separate cost, are required for CNC machining. Common raw materials for metal fabrication are brass, steel, aluminum, and stainless steel. Common engineering plastics are nylon, acrylic, and ABS.

Due to their special qualities and difficult processing, certain of these metals, including titanium and Inconel, will cost more. However, because they are readily available and simple to produce, materials like steel and aluminum are utilized extensively in CNC machining and are comparatively less expensive.

Common Metal Raw Materials For CNC Machining | |||

Raw Material | Characteristics | Unit Price (USD/lb) | Grade |

Aluminum | Lightweight, corrosion-resistant | $1.00 - $3.00 | $$ |

Steel | High strength, versatile | $0.50 - $1.50 | $ |

Stainless Steel | Corrosion-resistant, heat-resistant | $1.50 - $3.50 | $$ |

Brass | Excellent conductivity, decorative | $2.00 - $5.00 | $$$ |

Titanium | High strength-to-weight ratio, biocompatible | $8.00 - $15.00 | $$$$ |

Inconel | High-temperature resistance, corrosion-resistant | $10.00 - $20.00 | $$$$$ |

Common Plastics Raw Materials For CNC Machining | |||

Raw Material | Characteristics | Unit Price (USD/lb) | Grade |

ABS | Impact-resistant, easy to shape | $1.00 - $2.00 | $ |

Nylon | High tensile strength, wear-resistant | $2.00 - $4.00 | $$$ |

PEEK | High-temperature resistance, chemical resistance | $20.00 - $50.00 | $$$$$ |

Polycarbonate | Transparency, impact-resistant | $2.00 - $4.00 | $$$ |

Acrylic | Optical clarity, scratch-resistant | $2.00 - $5.00 | $$$ |

Polyethylene | Low cost, chemical resistance | $0.50 - $2.00 | $ |

Machining process

Setup Cost

The setup cost in CNC machining accounts for the expenses incurred before the actual production begins. Apart from the objective factors like the complexity of the product, the subjective skill level of the machinist also plays a significant role.

The simple truth is that a skilled and advanced machinist will adjust the machine much faster than a junior one.

Senior machinists often cost between $30 and $40 per hour, whereas junior machinists need between $15 and $25 per hour.

Process Running Cost

Process operating costs refer to the costs incurred during the actual production process, from the time the machine is successfully adjusted until the product is processed and removed from the machine.

This part of the usual costs include: machine operating costs and the cost of the operator assisting in product production. For example, after the first process is completed, the fixture needs to be replaced for the second process. After one product is completed, the technician needs to remove the finished product and replace it with a new one:raw material or semi-finished products.

In addition, the operating costs of CNC machine tools include energy consumption, tool wear and maintenance costs. These factors are explained in more detail below.

Surface Treatment Cost

The cost of surface treatment in CNC machining might vary based on the particular procedure and the product's size. Commonly used surface treatments that are less expensive are passivation and chromate, while coating and anodizing are more costly.

Common cost levels for surface treatment processes are as follows: | ||

Surface Treatment | Purpose | Grade |

Anodizing | Increase corrosion resistance, improve appearance | $$$ |

Powder Coating | Enhance weather resistance, prevent corrosion, enhance appearance | $$$ |

Electroplating | Improve corrosion resistance, improve conductivity | $$$$ |

Painting | Prevent rust, improve appearance | $$$ |

Chemical Film Coating | Increase corrosion resistance, improve conductivity | $$$$$ |

Passivation | Enhance corrosion resistance, improve corrosion resistance of stainless steel surfaces | $ |

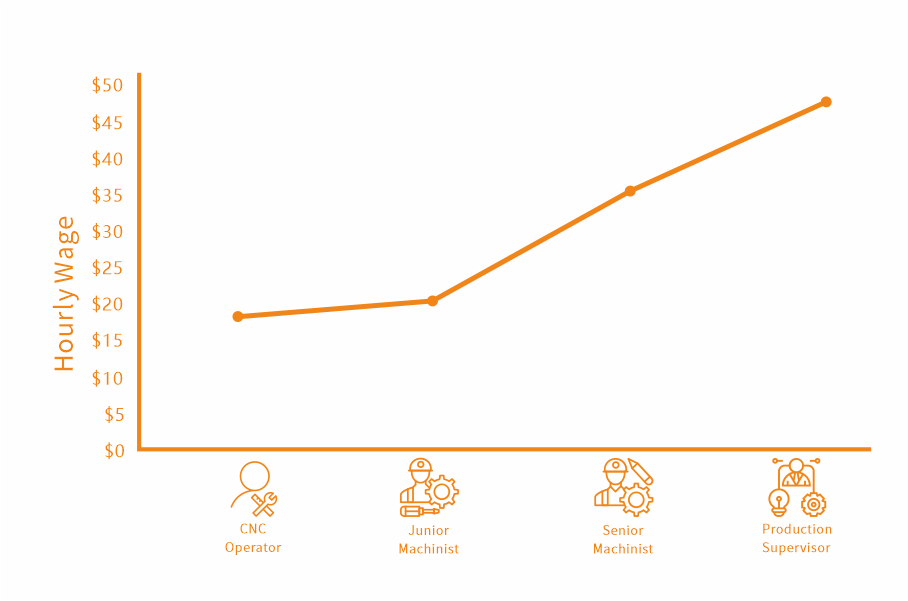

Labor Expenses

Labor costs are a major factor in CNC machining charges, in addition to setup and machining costs. This covers the pay of different employees who work in the production process.

These are the main labor expenses:

Salary of Machinist:

Senior Machinist: Depending on experience and region, a senior machinist's typical hourly pay is from $25 to $35.

Junior Machinist: The average hourly pay for a junior machinist is between $15 and $20.

Salary of Operator:

CNC Operator: A CNC operator may expect to make between $12 and $18 per hour on an hourly basis.

Production Manager's Salary:

Production Supervisor: A production manager's yearly compensation could vary from $60,000 to $100,000 based on expertise, location, and business size.

These numbers give a broad picture of the labor expenses related to CNC machining operations. Factors like as skill level, geographic location, and corporate policies may affect actual salaries.

Additional Costs About CNC Machining

Apart from the primary prices linked with CNC machining, there exist multiple other charges that must be taken into account in the comprehensive cost analysis:

1 Cost of Tools:

Particular tools are frequently needed for various CNC machining operations, including drilling, milling, and turning.

The initial cost of cutting tools as well as their regular replacement or sharpening due to wear and tear from use are included in tooling costs.

2 Fixture Costs:

Specialized tools called fixtures are used to keep the workpiece firmly in position while it is being machined.

Costs may increase for the design and construction of fittings made specifically for each distinct component.

3 Maintenance Costs:

To guarantee maximum performance and lifespan, CNC machines require routine maintenance.

Routine inspections, lubrication, and necessary component replacement or repair are all included in maintenance expenditures.

4 Energy Costs:

The spindle motors, cooling systems, and auxiliary equipment of CNC machines are all powered by electricity.

The effectiveness of the machine, the number of hours it is operated, and the cost of electricity in the area all affect energy expenses.

5 Overhead charges:

These include facility rent, insurance, utilities, and administrative charges, among other indirect costs related to operating a CNC machining business.

These expenses can be broken down by machining task to ascertain the actual cost, and they also add to the overall overhead load.

6 Quality Control Costs:

Ensuring product quality through inspection and testing adds to the overall cost of CNC machining.

Quality control costs include the labor, equipment, and materials required for dimensional verification, surface finish analysis, and defect detection.

For example, some high-precision parts require relatively advanced inspection equipment, such as CMM, to assist in inspection.

7 Transportation and Logistics Costs:

Shipping raw materials to the machining facility and delivering finished parts to customers incur transportation costs.

Logistics expenses may include packaging, handling, and storage of materials and products throughout the manufacturing process.

Manufacturers may have a more thorough grasp of the overall costs related to CNC machining and make well-informed decisions to maximize cost-efficiency by factoring in these additional charges.

Cost Analysis Across CNC Turning and 3-Axis/5-Axis CNC Machining

CNC Turning

CNC Turning Costs for Medium Part

Dimensions: Length - 80 mm, Diameter - 25 mm, Special Feature - Internal threading;Surface finishes: Aluminium(black oxide); stainless steel (passivated).

Here's a detailed breakdown of the cost analysis for medium-sized CNC turned parts with internal threading, taking into account various quantities ordered and materials utilized:

This in-depth analysis sheds light on the intricacies of CNC turning costs for medium-sized components, highlighting substantial savings as the quantity increases.

For instance, transitioning from a single unit to 100x in aluminium leads to a remarkable cost reduction of 87.2%.

Moreover, scaling up to 500x and 1000x quantities results in even more significant savings, emphasizing the efficiency and scalability of CNC turning processes.

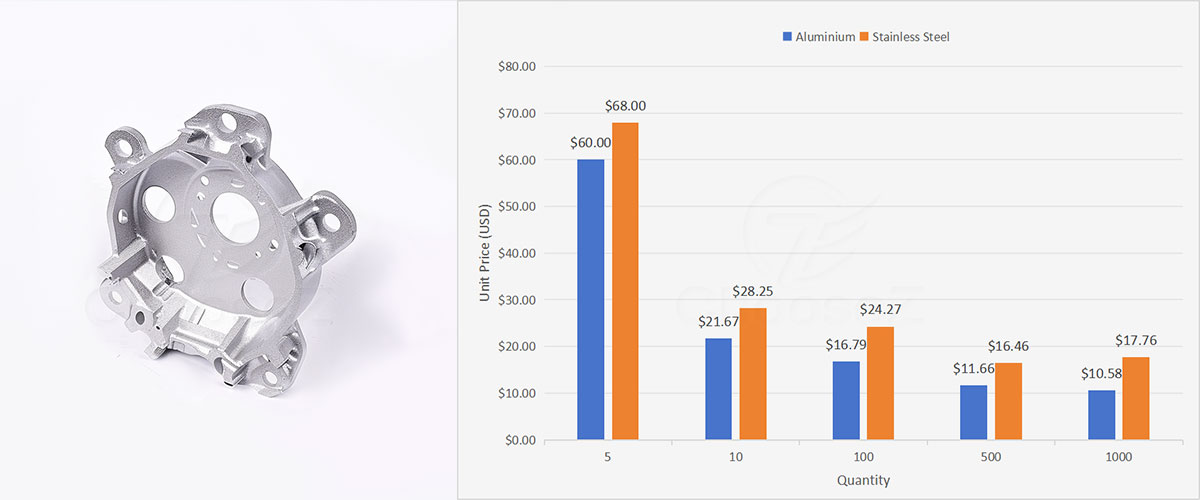

3-Axis CNC Machining

Dimensions: Height - 30 mm, Diameter - 60 mm

Below presents a comparison of costs between Aluminium and Stainless Steel for a basic CNC-machined part. The variations in pricing and lead times are outlined based on the quantity of parts ordered.

Transitioning from 5x to 100x in Aluminium results in a 51.02% reduction in unit price, with further savings up to 1000x. Similarly, Stainless Steel exhibits decreasing unit prices with increasing quantities, though with slightly lower cost savings.

This analysis underscores the impact of production volume on CNC machining costs, emphasizing the importance of optimizing quantities to achieve significant cost efficiencies.

5-Axis CNC Machining Costs

Dimensions: Height - 40 mm, Diameter - 90 mm

Below presents a comparison of costs between Aluminium and Stainless Steel for a basic CNC-machined part using 5-axis machining. The variations in pricing and lead times are outlined based on the quantity of parts ordered.

Transitioning from 5x to 100x in Aluminium results in a 72.01% reduction in unit price, with further savings up to 1000x. Stainless Steel exhibits similar trends with slightly lower cost savings.

This analysis underscores the impact of production volume on CNC machining costs, emphasizing the importance of optimizing quantities to achieve significant cost efficiencies.

How To Reduce CNC Machining Costs?

Raw Material Selection

Choose Correct Raw Material

Selecting the appropriate raw material according to the drawing is paramount for successful machining. However, when faced with similar materials that vary significantly in price, considering alternative options can be beneficial.

For instance, while the price of material 1.2510 may be relatively high, we can explore substituting it with 4Crr13. Not only is 4Crr13 more affordable, but it also does not compromise the functionality of the product.

Raw Material Form

For exceptionally large-sized products, opting for prefabricated aluminum profiles can be advantageous. These profiles closely resemble the final dimensions of the product, thereby reducing machining complexity and minimizing material wastage.

Optimized Surface Treatment

Combine 2 Processes into 1

For instance, a product may require both black anodizing and natural chromate conversion coatings.

Traditionally, after the initial machining, the part would undergo black anodizing first, followed by a return for precision hole machining, and then the application of the natural chromate conversion coating to ensure dimensional accuracy.

However, to streamline production time, both surface treatments can be completed in a single operation. By sealing the precision holes before black anodizing, the part can proceed directly to chromate conversion coating after anodizing, saving at least 4-5 days of production time.

Avoiding Multiple Finishes

Choose highly machinable materials like aluminum when available to reduce costs. As-machined surface finishes are often sufficient and economical, compared to multiple finishes. While some surface finishes are essential for component properties, use them sparingly to minimize costs. Avoid applying different finishes on various surfaces of a component to keep finishing specifications uniform and costs down.

Select Matched Machines

Choosing the appropriate machining equipment for the task is essential to maximize productivity and reduce expenses. Optimizing performance and lowering the possibility of mistakes or rework are ensured when a machine's capabilities are matched with the project requirements.

While larger components might need the capability of heavy-duty machining centers, smaller, highly precise parts might be better suited for CNC machines with finer accuracy.

Manufacturers can increase productivity and produce better results by matching the machine's specifications to the particular requirements of the project.

Production Volume

Consideration of production volume is essential for cost-effective CNC machining. Understanding the anticipated quantity of parts required allows manufacturers to optimize workflows, batch sizes, and tooling strategies accordingly.

For higher volume orders, economies of scale can be leveraged to reduce unit costs through efficient batch processing and optimized setups.

Conversely, for smaller production runs, flexibility and quick changeovers become paramount to minimize downtime and maintain cost-effectiveness.

By aligning production volume with machining strategies, manufacturers can achieve optimal efficiency and cost savings.

The Necessity of Precise Dimensions

A CNC machining project's success depends critically on having precise and accurate dimensions. Modest departures from the required tolerances may result in product malfunctions, assembly troubles, or functional problems.

Precise dimensioning not only improves product quality but also lowers lead times and costs by reducing the need for scrap, rework, or post-processing modifications.

Tight tolerances and the appropriate degree of precision can be maintained and obtained in CNC machined parts with the use of sophisticated metrology instruments, strict quality control procedures, and skilled machinists.

Use Standard Hole Sizes

In CNC machining, selecting standardized hole sizes during the design phase brings numerous benefits.

Firstly, it simplifies assembly by enabling the use of commonly available screws and fasteners, reducing the need for specialized or custom hardware.

Additionally, standardized hole sizes eliminate the necessity for non-standard measuring tools during production, streamlining the inspection process and saving both time and procurement expenses.

Adhering to established industry standards for hole dimensions facilitates smoother production workflows and ensures compatibility with off-the-shelf components, contributing to overall cost reduction and efficiency gains.

No CNC Lettering ,but Laser Engraving

In production processes, laser engraving delivers significant time and cost reductions as compared to CNC engraving.

For lettering or labeling, laser engraving eliminates the requirement for tool changes and setup that come with CNC machining. This efficient method lowers operating costs and shortens lead times for production.

Furthermore, more text types, sizes, and designs are possible with laser engraving, allowing for precise customisation without sacrificing effectiveness.

Manufacturers may increase design variety, reduce production costs, and expedite turnaround times by utilizing laser engraving technology. This optimizes the CNC machining process for better performance and competitiveness.

Kevin Zhang

NPI Supervisor

Zhang has been working as an NPI (New Product Introduction) manager for more than ten years. Every endeavor gains energy from his vibrant personality. In his own time, Kevin plays soccer competitively and coaches neighborhood young teams, showcasing his leadership abilities both on and off the field.

You Might also Like

View all →

CNC Milling Machine Operation: Ready to Master the Key Skills?

Read More →

How Much Does CNC Machining Cost?

Read More →