Manufacturing CNC Machining Parts Complete Travel From Drawing to Product

The quick answer

CNC machining, a manufacturing technique, leverages computerized controls to operate machinery and cutting tools, molding raw materials such as metal, plastic, or composites into bespoke components.

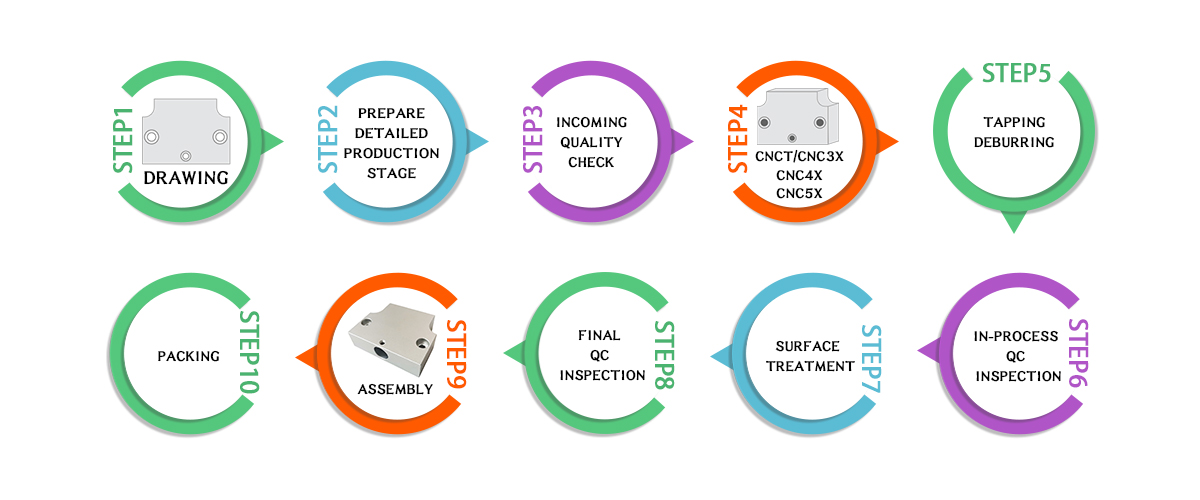

The journey of fabricating a CNC-machined part involves drawing, prepare detailed production stage(PDS), Incoming quality check(IQC),CNC machining(CNC/CNCT), Tapping/Deburring(TP/DB), In-process QC,inspection(IPQC), Surface treatment(ST), Assembly(ASSY), Final QC inspection(FQC), Packing (PA),total 9 steps CNC machining process.

What is CNC machining?

CNC, short for computer numerical control, refers to the automation of machine tools and devices through computer commands rather than manual operation by an operator. The core CNC processes encompass various techniques like milling, turning, drilling, grinding, and sawing, with CNC milling and CNC turning being the most prevalent and widely utilized among them.

Advantages of CNC Machining

Advanced precision milling machines operate through software programs that repeatedly execute tasks using fixed tools along predefined routes. This systematic approach maximizes the efficiency of raw material utilization, allowing for a smarter and more effective use of available resources. By leveraging cutting-edge CNC technology, manufacturers can significantly curtail waste, playing a vital role in minimizing material wastage and amplifying overall resource efficiency.

Operating autonomously, precision turning machines stand as a shield against potential human errors that could seep into the manufacturing process. The reliance on codes and software programs guides these machines through an end-to-end process, ensuring an unparalleled level of accuracy without any room for flaws or discrepancies. This seamless operation, devoid of manual intervention, guarantees a level of precision that humans might struggle to achieve, enhancing the overall quality and reliability of the produced components.

CNC machines don't have downtime; they work round the clock, unlike human workers who require rest and breaks. This continuous operation ensures that CNC machining maintains unparalleled accuracy and efficiency, minimizing material wastage. As a result, CNC machining and milling stand out as highly efficient, rapid, and scalable production methods, offering cost-effective solutions.

What is CNC Machining parts?

The spectrum of CNC machining parts encompasses a diverse range, from sturdy steel components to lightweight aluminum parts, showcasing the versatility and adaptability of this manufacturing technique across various materials and industries.

Process of CNC machining

CNC drawings serve as meticulous, accurate blueprints detailing the intricate specifics of a part or component to be crafted using CNC machining. These drawings come in varied formats, commonly found as 2D (PDF), 3D (CAD), or jpg files.

Within these drawings, a wealth of crucial details is encapsulated, including dimensions, tolerances, material specifications, drawing versions, and any other pertinent information essential for the precise production of the intended part.

Prepare detailed production stage(DPS)

Prior to commencing formal CNC manufacturing, a meticulous and comprehensive production schedule is imperative, referred to as the Detailed Production Stage (DPS).

Check the Drawing: Scrutinize the drawing to ensure accuracy and completeness, verifying the inclusion of all necessary information. Validate the consistency between 2D and 3D representations.

Conceptualize: Develop a preliminary vision of the final product, considering the manufacturing process intricacies, and devise a method for its realization.

Design Phase: Based on the envisioned product, craft tailored fixtures and customize specialized tools to suit the manufacturing requirements.

Programming: Develop a program aligned with the procedural route, ensuring it corresponds accurately to the envisioned process. Subsequently, issue the finalized drawings for production.

Incoming quality check(IQC)

Various raw materials are employed for CNC machining processes, encompassing a diverse range:

Aluminum: 6061-T6, 7075-T6, 7050, 2024, 5052, 6063, MIC6

Stainless Steel: 303, 304L, 316L, 410, 416, 440C, 17-4PH, Nitronic 60

Others: ABS, Brass, Copper, Nylon, PVC, Titanium, Zinc, and more.

Prior to commencing production, a stringent quality check of the raw materials is imperative. This check involves examining the dimensions (length, width, height) and reviewing material composition reports to ensure they meet the required specifications.

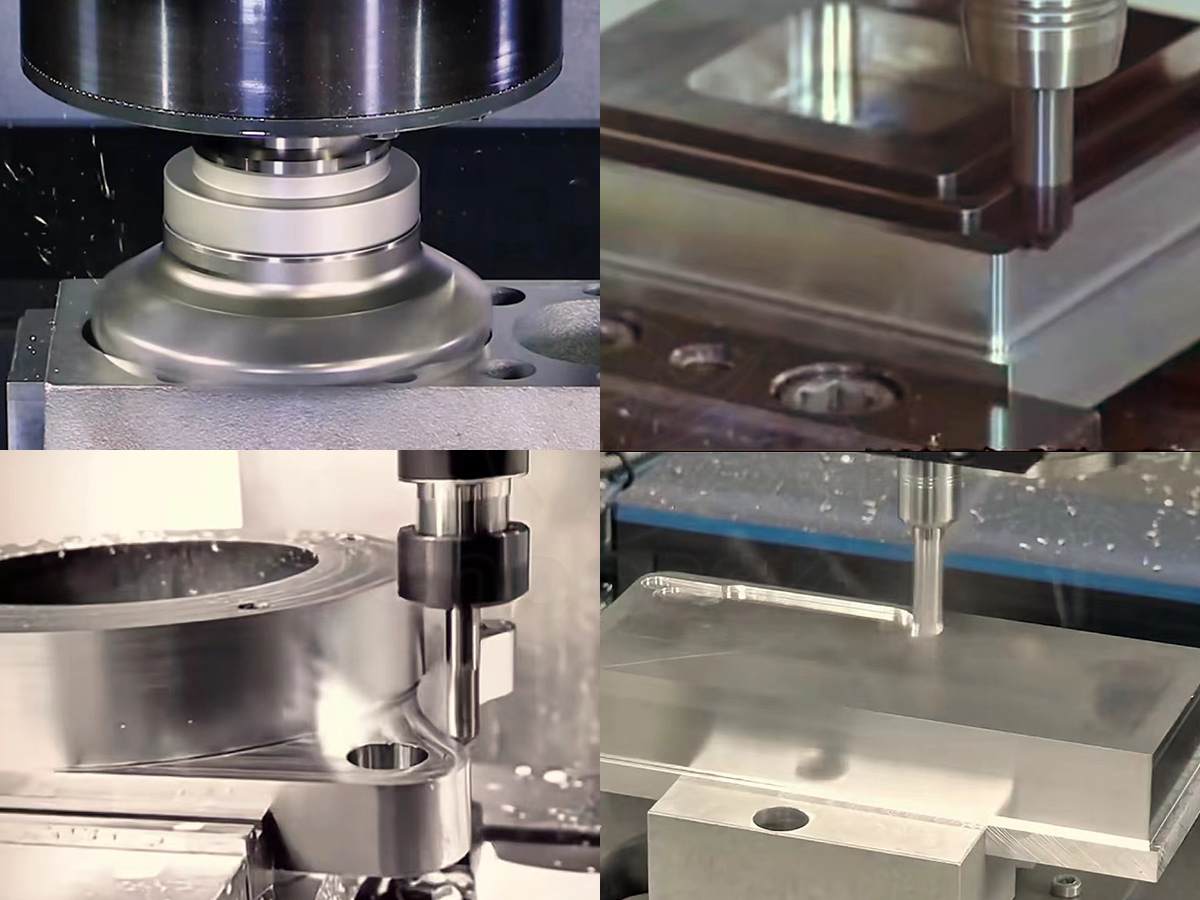

CNC machining(CNCT/CNC3X,4X,5X)

The machining process unfolds through a sequence:

Machine Selection: Aligned with the Detailed Production Stage (DPS), the optimal CNC machining equipment is chosen.

Fixture and Setup: Selection and configuration of jigs and fixtures are carefully undertaken.

CNC Machining: Execution of the machining process.

In-Process Quality Control: Vigilant quality checks commence with the initial piece at each stage and the first workpiece.

The machining process unfolds through a sequence:

Machine Selection: Aligned with the Detailed Production Stage (DPS), the optimal CNC machining equipment is chosen.

Fixture and Setup: Selection and configuration of jigs and fixtures are carefully undertaken.

CNC Machining: Execution of the machining process.

In-Process Quality Control: Vigilant quality checks commence with the initial piece at each stage and the first workpiece.

TP refers to tapping, where the appropriate tap tool is selected based on the blueprint and utilized in the CNC machines, lathe machines, or specialized tapping machines for processing.

DB, or deburring, occurs post-CNC machining, aiming to eliminate small imperfections, called burrs, from machined metal products. Common deburring methods include manual deburring, grinding and rolling, electrochemical deburring, hole deburring, and brushing.

IPQC (In Process Quality Control) entails the procedural oversight from raw material acquisition through the final packaging of manufactured items. This involves inspection post-machining but before surface treatment.

The focus lies in verifying the dimensions of semi-finished products and visually inspecting them to ensure readiness for the subsequent step: surface treatment.

Surface treatment(ST)

Surface treatment, often abbreviated as ST, constitutes an additional process applied to material surfaces to augment functions like resistance to rust and wear or to enhance their aesthetic appeal.

Typically conducted off-site from the CNC machining facility, surface treatment facilities are often in close proximity to machining units to ease transportation and collaboration. Various surface finish options are employed in CNC machining, including Alodine, Anodizing, Black Oxide, Electroless Nickel Plating, Electropolishing, Hand Polishing, Media Blasting, Nickel Plating, Passivation, Powder Coating, Tumbling, Vapor Polishing, Zinc Plating, and more.

This treatment phase typically spans 1-3 days. Simpler treatments like passivation may conclude within a day, while more intricate procedures like anodizing or nickel plating might require three or more days to complete.

FQC, or Final Quality Control, designates the meticulous inspection conducted by quality control experts on each finished product using essential tools before the packing stage. This final assessment aims to unearth any nonconformities, identify reasons for disqualification, and address them by initiating repairs. Subsequently, the products undergo re-inspection through the FQC process.

Inspection tools commonly employed for machined finished products encompass calipers, altimeters, projectors, and CMMs (Coordinate Measuring Machines). The selection of these tools depends on the product's size and tolerance specifications, ensuring precise measurement.

FQC quality assurance often adheres to the Acceptance Quality Limit (AQL) standards. At ChooseZ, our quality assurance for First Article (FA) orders involves comprehensive inspections of all quantities and dimensions. For mass production orders, we apply AQL guidelines, conducting 100% inspections for critical dimensions.

Assembly(ASSY)

Assembly is referred to in industrial manufacturing as all the processes needed to assemble objects with a geometrically defined shape.Here are two ways of assembly in CNC machining in industry:

-Integrating Standard Parts: This process involves incorporating standardized elements, such as attaching a threaded sleeve to the finished CNC machining part;

-Integrating Subcomponents into an Assembly: Products may consist of multiple components, where one part, termed the "son," is assembled onto another, termed the "mother." For instance, if part A represents a subcomponent and part B denotes the main structure, joining part A to part B is a fundamental step in the assembly process.

Apart from the mentioned processing steps, several additional common procedures include heat treatment, stress release, and marking.

Just before shipping, the final step involves packaging. Common packaging materials for CNC machining encompass roller sponge, sponge bags, honeycomb cardboard, carton boxes, and more. However, for exceptionally heavy or large products, standard packaging isn't sufficient. hat's when the need for robust, customized wooden crates arises, ensuring absolute protection against any potential damage during transit.

At ChooseZ, we offer the flexibility of shipping your precision CNC machined parts both by air and sea. Strategically situated in Guangzhou City, Guangdong Province, South China, our proximity to major ports like Guangzhou, Shenzhen, Zhanjiang, and Shantou ensures seamless sea shipments. Additionally, with easy access to international airports such as Guangzhou Airport, our air transport services guarantee expedited deliveries. Whether you prefer the efficiency of air transport or the cost-effectiveness of sea freight, we ensure your custom parts reach you reliably and promptly, meeting your delivery preferences worldwide.

Conclusion

Above is the complete process about a CNC machining part from beginning to finished good.

Drawing->DPS->IQC->CNCT/CNC3X,4X,5X->IPQC->TD/DB->ST->FQC->ASSY->PA, This is a seemingly simple task but requires sustained attention.Because any mistake in any link may lead to the scrapping of parts directly.

ChooseZ CNC machining service

At ChooseZ, we specialize in an array of machining services to craft customized CNC metal/plastic parts that precisely match our clients' unique specifications. Our seasoned machinists at ChooseZ possess extensive expertise and access to cutting-edge resources, enabling us to handle intricate machining tasks with ease.

Situated in Dongguan, Changan town, famously known as the hub of "The World's Factory," our facility boasts easy access to external resources such as raw materials, surface treatment, wire cutting, and EDM. This strategic location enables us to offer competitive prices and top-tier customer service to all our clients.

Our production turnaround time typically ranges between 3 to 21 days, depending on the complexity of the parts. We strive for almost real-time delivery, allowing our clients to avoid unnecessary inventory storage costs.

Keen on monitoring the daily production progress? We've got you covered! We provide detailed production schedules with weekly updates. For urgent orders, we go the extra mile by offering daily picture and video updates. Our commitment to transparency means you're always informed about our factory's operations and production processes.

We understand these aspects matter to you, which is why they're our priority.

You Might also Like

View all →

CNC Milling Machine Operation: Ready to Master the Key Skills?

Read More →

How Much Does CNC Machining Cost?

Read More →